Materials from our own weaving mill

Air quality begins

with choosing the right material.

And what is the right material?

The one that is made with tradition in our family weaving mill in Denmark.

Family tradition

In 1972, the KE Fibertec Væveri weaving mill was established in Denmark, focusing solely and exclusively on the production of textiles for air distribution.

Although the family business has become part of the KE Fibertec Group over the years, of which Euro Air is also a member, the leadership of the weaving mill is still held by members of the founding family.

Today, it is already the 3rd generation, represented by Mr. Frank Hansen.

Exclusive fabric production

Our weaving mill specializes in the production of two types of fabrics, DFC-HT and TCS, both of which meet the certification criteria of Cradle to Cradle.

For production, we use non-flammable polyester fibers, which are obtained from the same granules for both materials. The differential properties of the materials are then determined by the distinct processing of the yarn.

The fabric DFC-HT is made from longer and parallelly arranged fibers. On the other hand, TCS is made from shorter fibers that slightly protrude, giving the woven material a greater ability to capture dust.

We also offer a third material, DFC-0. However, due to its specific impermeable properties, we do not produce it ourselves but purchase it from a reputable supplier in Italy.

In the yarn, we carefully monitor the oil content.

This is crucial to ensure the unique property of air permeability through the fabric.

Air permeability

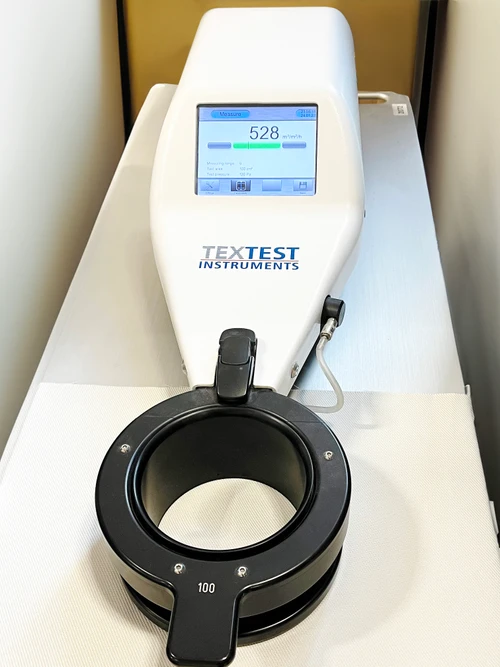

Permeability is a unique property of Euro Air materials that allows air to pass through without the need for material perforation.

This unique property of fabrics is ensured by special warp preparation, where it's crucial to maintain a constant yarn tension from the beginning to the end of winding onto the coil. The goal is to wind the yarn evenly across the entire width of the coil. During weaving, we then adjust the weft density to achieve the desired permeability.

To guarantee the accuracy of permeability, we perform control and measurement after every 600 square meters of fabric. The final step in the weaving process is thermal fixation, which eliminates any remaining fabric shrinkage tendencies and ensures that the fabric maintains the same length and air permeability even after system servicing.

Each of our materials undergoes multiple inspections throughout the entire process and is equipped with a special barcode. This allows for tracking the entire production process, from the installed system to the yarn.

Weaving mill

Take a look at our weaving mill

Dyeing and Printing

We are aware of the importance of environmental protection, and therefore, we have decided to abandon traditional dyeing of already woven white rolls, which consumes up to 25 l/kg of water.

Instead, we dye and print using 3 alternative methods that are more environmentally friendly:

- Cone Dye: This method involves dyeing white yarn on a cone through gradual dye penetration. This method consumes only 5 l/kg of water.

- DopeDye: The most eco-friendly method, where dry dye is added directly to the granule production process, meaning no additional water is added to the process.

- Transfer: With this technique, color is transferred from paper to fabric in a printing machine. This allows for transferring more than 1,600 colors, as well as various patterns and prints, onto the fabric.

By deciding to stop using the traditional method of dyeing entire rolls, we have achieved water savings of up to 67%.

A responsible attitude

Waste generated during the weaving of our fabrics is considered a valuable resource.

We strive to apply the principles of the circular economy throughout our production.

- Leftover yarn serves as a primary raw material for producing cords, which are then used for suspending ducts in tracks.

- Remaining plastic spools are granulated and utilized for the production of other items.

- Fabric scraps find application as input material for other companies, such as in the production of acoustic panels.

Our goal is to achieve zero final waste production, as we see every generated waste as an opportunity for further development and innovation.

Robotic assistant

Albot: the youngest member of our team

In March 2019, we expanded our team with the addition of Albot, a robot tasked with one of the most demanding duties - preparing yarns for weaving.

Thanks to Albot, our employees can focus on less physically demanding yet equally important tasks.

This advancement allows us to more efficiently allocate work tasks while maintaining the quality of our fabrics.

Get in touch with us

The refreshing air you desire is just one click away.Our expert sales representatives are ready to advise you on design or handle any project.

With us, you can expect a response to your request within 24 hours.