How to identify high-quality textile ducting? Guide in 5 steps

You don’t notice high-quality air distribution systems because they don’t disturb you. No drafts, no temperature fluctuations, no stale odors after years of operation.

But when something is off, you feel it immediately. A cold breeze on your neck, uneven temperatures across the room, or an unpleasant airflow whose source you can’t pinpoint.

So how can you tell if you’re dealing with a truly high-quality textile air distribution system?

1. Material is not just fabric. It is the foundation of quality.

In textile air distribution systems, it is not just the layout that matters but also the material from which they are made. High-quality fabric ensures even air distribution, minimizes unwanted effects, and withstands demanding operating conditions. But how can you tell if you are holding a truly reliable material?

The foundation of quality lies in the yarn. The manufacturer should be able to provide precise documentation of where the material comes from and how it was processed - from yarn to the finished and installed product. In the most advanced production processes, each piece of fabric can even be traced throughout its entire manufacturing journey, sometimes via a barcode system. This allows for full traceability at any stage of production, making it possible to verify what happened during manufacturing and how it might have affected the final product.

There is no single universal material for all installations. To ensure optimal performance, it is essential to choose the right air permeability for the fabric. A well-selected textile prevents the formation of dead zones and guarantees even airflow without unwanted turbulence in the direction of the flow.

Tip for You: If the material is too thin, easily tears, or the manufacturer cannot verify its origin, take caution. It is likely not a reliable material.

2. Precision manufacturing – every detail matters

When you look at textile air distribution systems, you might think it is "just a piece of fabric." In reality, each system is the result of precise manufacturing, where millimeters make a difference. The accuracy of workmanship not only affects how the system performs but also how long it lasts.

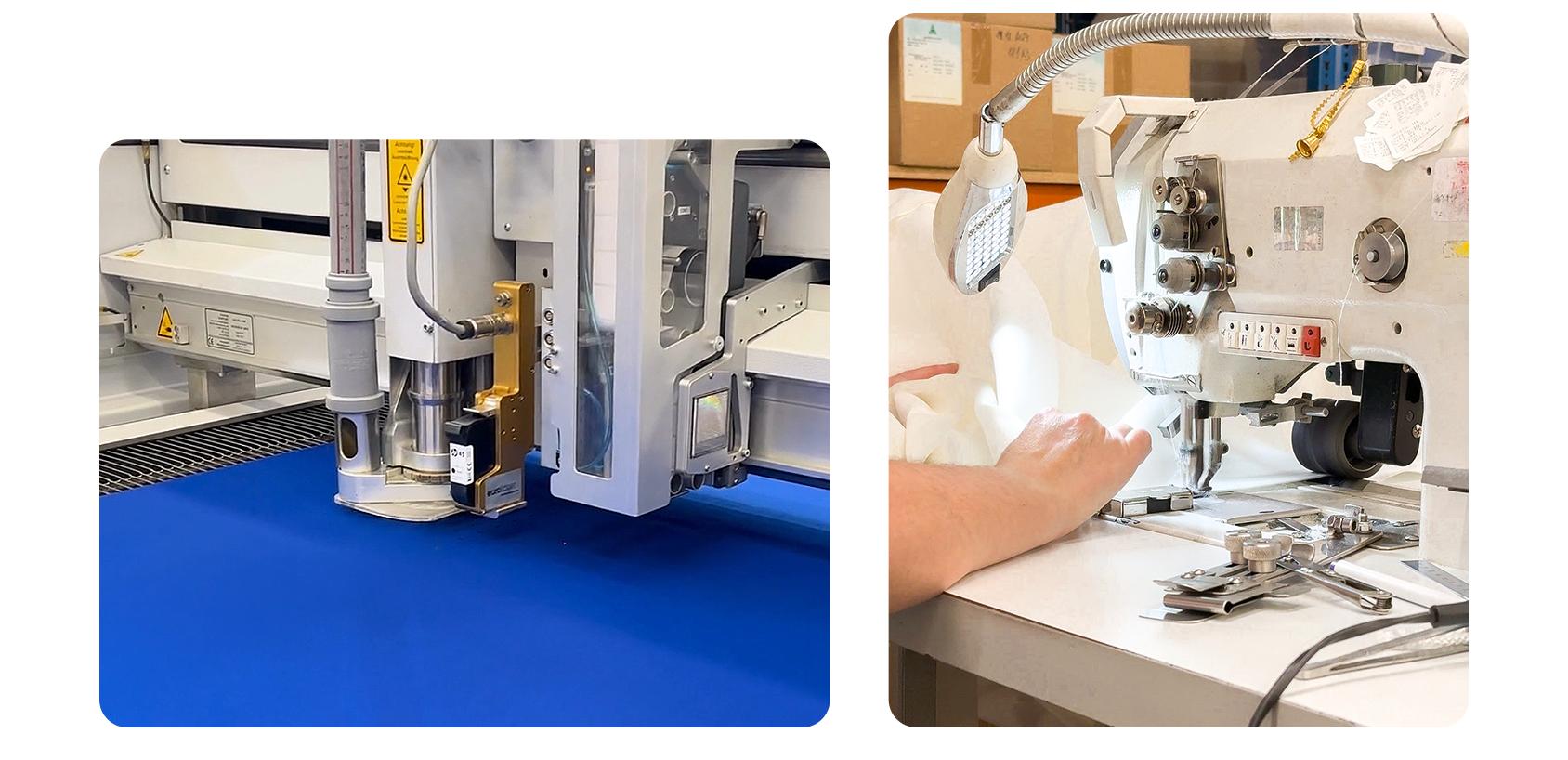

Modern production uses laser cutting, ensuring precise and clean edges with minimal waste. Yet, the final assembly always comes down to handcraftsmanship—and that is what sets apart an ordinary product from a truly high-quality solution. You can recognize this by carefully sewn zippers, always aligned at the same starting point, precisely stitched seams, and reinforced suspension elements that do not fray and stay securely in place.

Tip for You: Take a closer look. If the seams are uneven and the cords fray at first glance, it could be a sign of poor workmanship. True precision is visible in the details.

3. Final quality inspection reveals everything

Even the best-designed and precisely manufactured system may not be entirely flawless. That is why every product should undergo a thorough quality check before leaving the factory. A high-quality manufacturer leaves nothing to chance, ensuring that each system meets strict specifications and high standards of workmanship.

There is no automated system that can inspect every detail of a textile air distribution system better than a trained human eye. Every product should pass through the hands of experienced specialists who carefully examine seams, suspension elements, and overall compliance with production documentation.

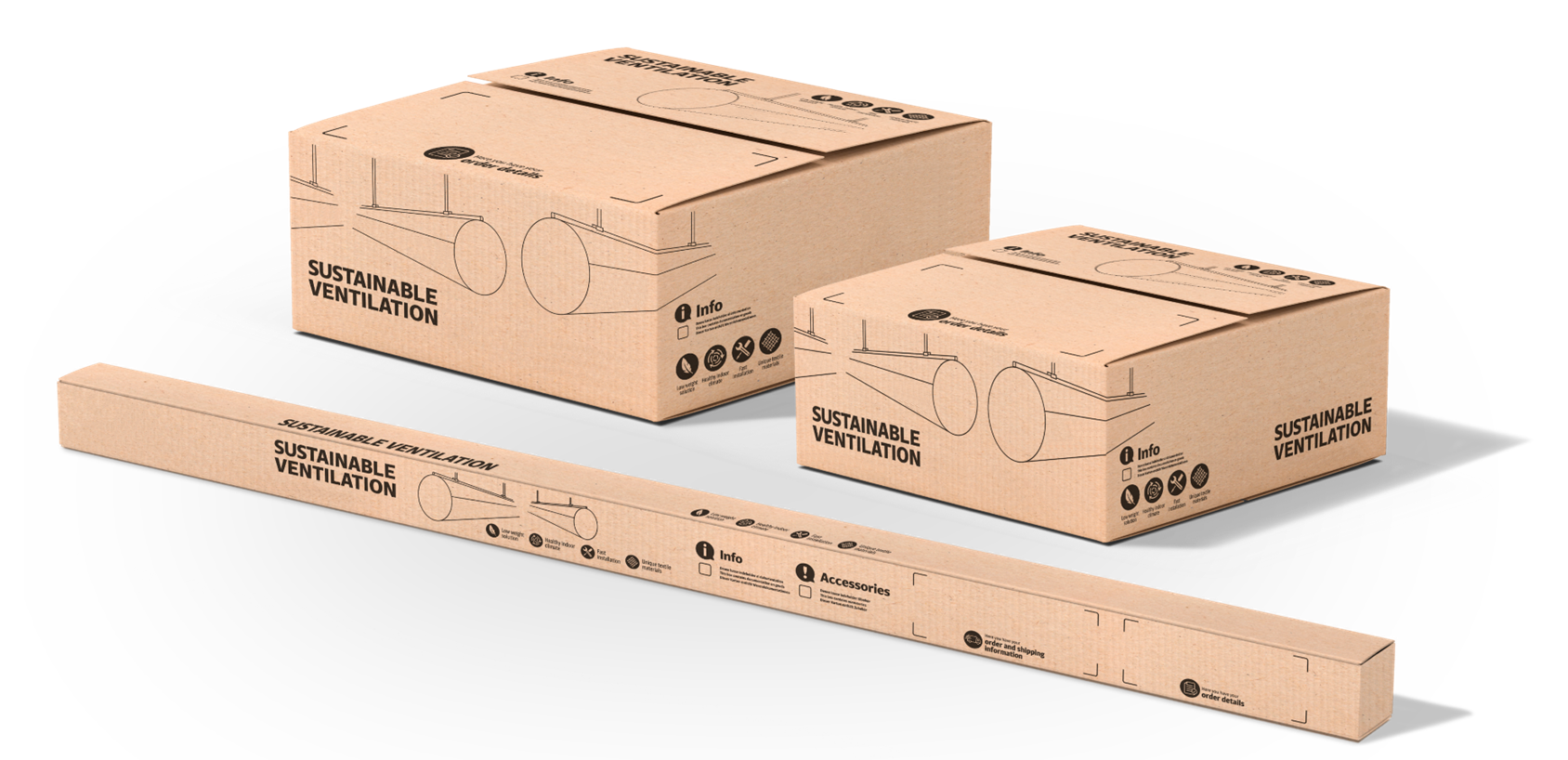

And then there is the packaging—a detail that often reveals more than you might expect. Clear labeling, well-organized components, and a carefully arranged box show that the manufacturer has considered not only production but also ease of installation.

Tip for You: When you open the box, everything should be neatly organized, precisely packed, and in perfect condition. If you see chaos, missing parts, or fraying fabric edges at first glance, there is a good chance that the quality control was not thorough enough.

4. Responsibility that goes beyond manufacturing

Modern projects are no longer just about performance and cost. More and more investors, architects, and designers are prioritizing sustainability. But how can you tell if a product is truly designed with the environment in mind?

A responsible manufacturer selects textiles that not only meet technical requirements but are also free from harmful chemicals. And if a product holds a Cradle to Cradle certification, it means it complies with the strictest international sustainability standards.

But sustainability does not stop at materials. The production of textile air distribution systems should also minimize waste. For example, laser cutting reduces excess fabric, leftover yarn can be repurposed for suspension elements, and water-saving dyeing techniques can significantly reduce water consumption compared to conventional methods. A high-quality manufacturer does everything possible to minimize waste.

The spirit of sustainability should extend all the way to the customer. Biodegradable boxes, PVC-free adhesive tapes, and hexacomb cardboard fillers for packaging can greatly reduce the carbon footprint compared to traditional EPS fillings.

Tip pro Vás: If a manufacturer talks about sustainability but cannot provide concrete proof, such as certifications, it is worth questioning how seriously they take their commitment.

5. Support & Service: Who helps you when you’re unsure?

The right partner does not just deliver a high-quality product—they also design it correctly. So how do you know you are in good hands?

Selecting the right material and system configuration is not the customer’s job—it is the expert’s responsibility. A high-quality manufacturer does not ask, "What material do you want?" Instead, they recommend the best solution based on the specific space. They also provide clear and prompt responses, whether it is a small project or a large installation. Every inquiry is taken seriously because good communication is key to a smooth project execution.

And what happens once the product is installed? The job is far from over. A manufacturer should offer technical support even after installation—whether it is for maintenance, system adjustments, or consultations for future projects.

Tip pro Vás: The right manufacturer does not just sell air distribution systems—they provide expertise. If you experience genuine interest, receive valuable advice, and feel supported from the start, you can be sure you are choosing a long-term partner, not just a one-time supplier.

Key takeaways from this article

- Material is the foundation of quality. It should be traceable back to the yarn, with proper properties and permeability to ensure optimal performance.

- Precision manufacturing starts with laser cutting, continues with handcrafted assembly, and results in a product where every component is thoroughly inspected. Quality is never checked at random, every detail should undergo a careful review.

- Truly responsible manufacturing prioritizes sustainability. It minimizes waste, uses eco-friendly packaging, and offers certified materials such as Cradle to Cradle.

- Support matters. An experienced manufacturer does not just deliver a product but also provides guidance on maintenance, ensuring it lasts for years.

When choosing textile air distribution systems, look beyond the product itself. True quality is not just in the material it is in the approach behind it.

YOUR SOLUTION

Looking for an air distribution system that meets all these criteria?We will design a tailor-made solution that ensures reliable performance for years to come.