Behind the Euro Air brand are people who truly know their craft.

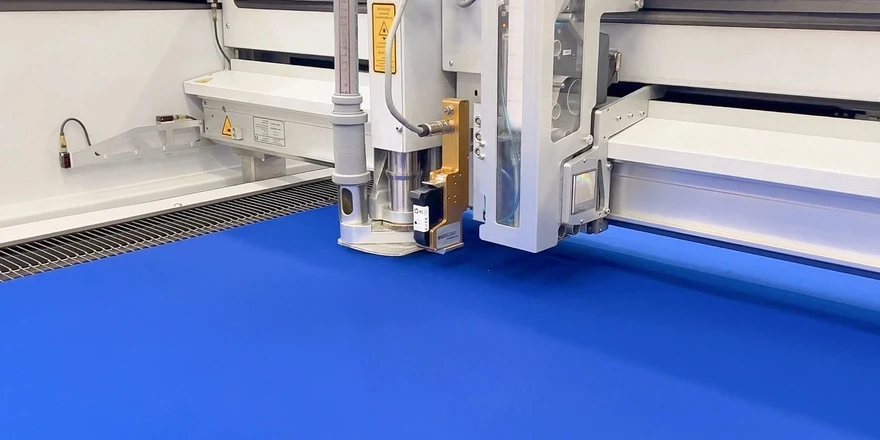

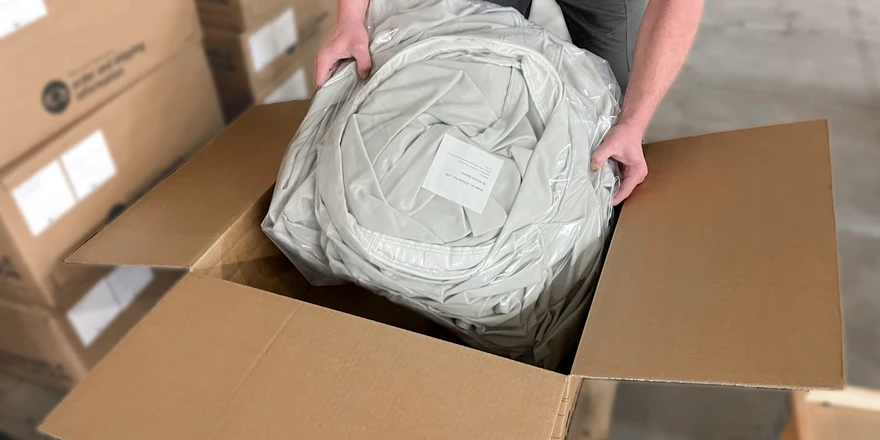

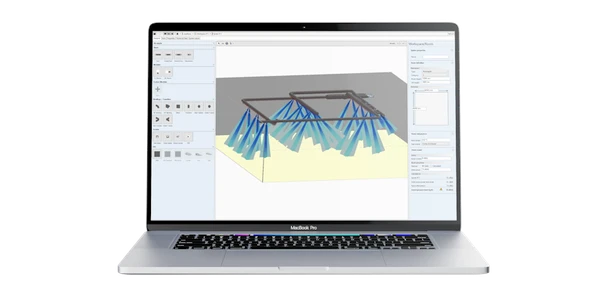

Technicians, seamstresses, cutters, and quality controllers, many of whom have worked together for years and know every stitch of the products they help create. Perhaps that’s why we naturally bring every project to the highest level of detail.

Our production takes place exclusively in Europe, in Varnsdorf in Northern Bohemia, where we build on a long-standing textile tradition, and in Vejen, Denmark, where our story began. We don’t outsource to low-cost countries. We’re committed to delivering true quality and take pride in genuine Czech craftsmanship.

Since 2007, we’ve been part of the KE Fibertec Group. Yet both our facilities still operate with the spirit of a family business.