CliniClowns

Installation up to 70% faster than with metal ducting.

Faster installation means less time on site, fewer people involved, and lower mounting costs.

Thanks to the lightweight construction, there’s no need for heavy machinery or complicated handling. The result? A smooth installation process, cleaner execution, and a reliable system.

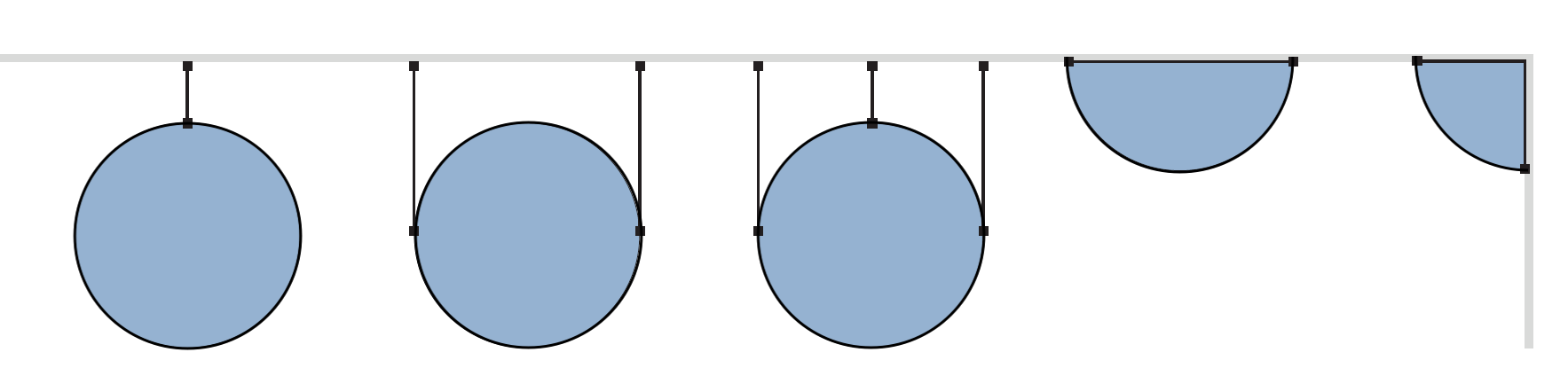

Textile ducting can be produced in three different shapes to suit any space and technical setup.

Thanks to this flexibility, it’s possible to find a solution for open halls, offices, and areas with limited installation options.

We offer three configurations so you can easily choose the most suitable option for each project and installation site.

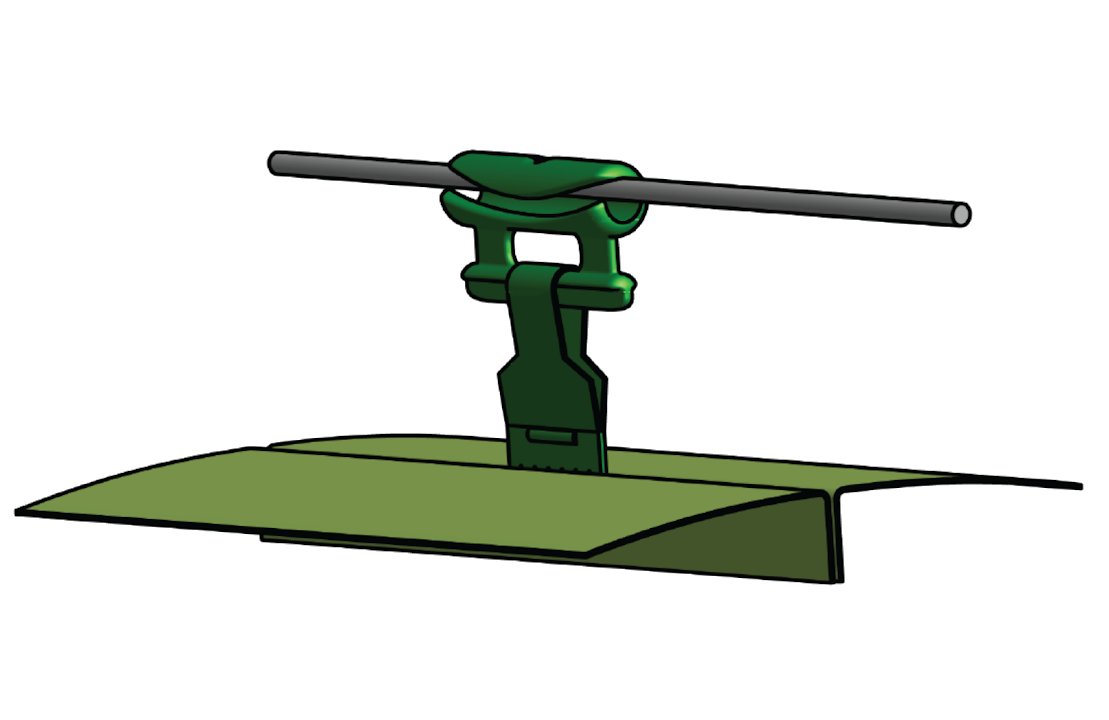

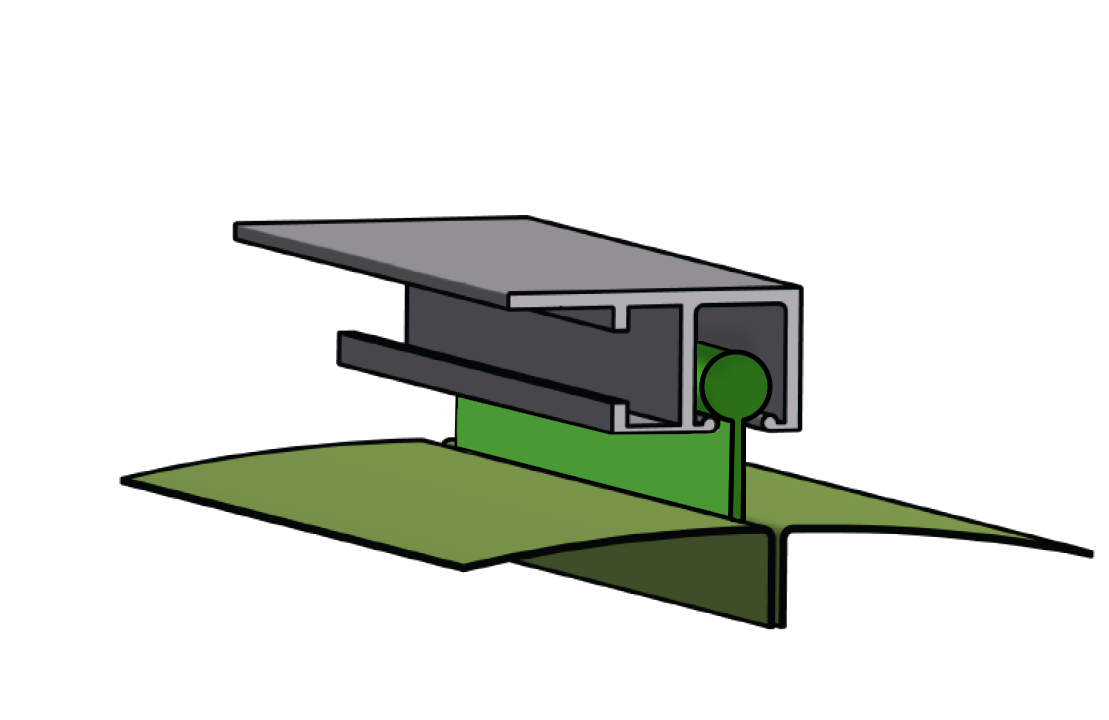

We offer two reliable and simple options for securing textile ducts. Each is designed to ensure fast installation and to keep the duct securely in place even during long-term operation.

Small plastic clips sewn directly into the textile duct. They allow for easy snapping onto a wire or sliding into an aluminium rail. In both cases, the solution is stable, doesn’t twist during handling, and allows smooth adjustment during mounting.

A fastening method using recycled yarn from the weaving mill, which is turned into a special cord sealed into a fabric strip and sewn directly into the duct. The whole element is then simply inserted into the aluminium rail.

The connection of fabric ducts to the air supply ducting is designed to be quick, reliable, and aesthetically pleasing. You do not need to improvise on site, as our product range includes all the components you need for easy connection to round or square supply systems or units.

A solution that is assembled around the supply pipe without a flange, and then the assembly joint is covered with a textile strap, ensuring a highly aesthetic connection.

A solution that fits onto a flange or a opening in the wall. All mounting components of the frame are hidden inside, ensuring a completely invisible connection.

A solution that mounts directly onto the flange, but here the mounting components are visible around the flange, which allows the frame to be mounted outside the corners of the flange or using a HVAC Clamp

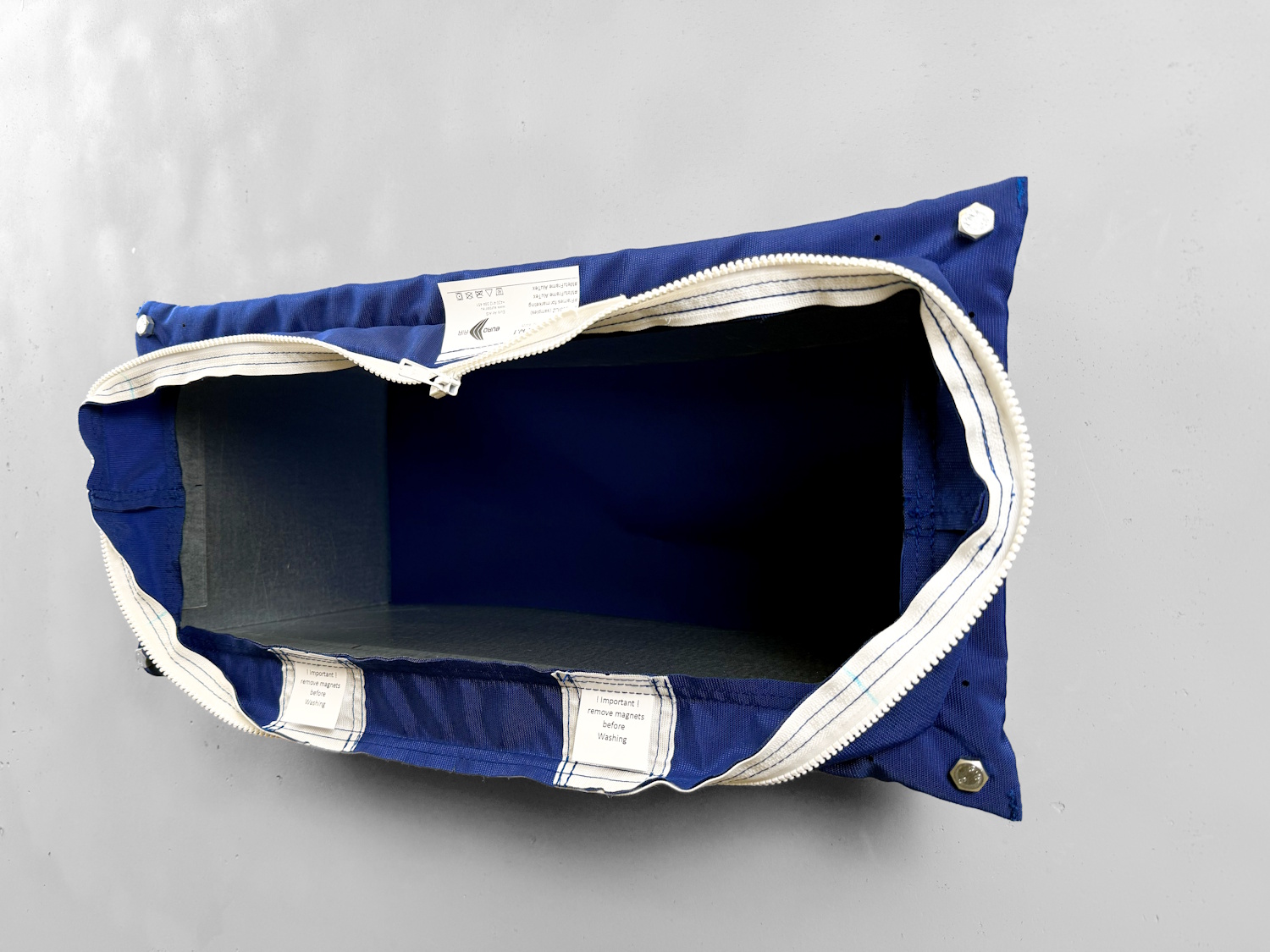

A premium solution that keeps textile ducting in perfect shape under all conditions.

They prevent sagging and protect the system during start-up, extending its service life and maintaining aesthetic value even when the fan is off.

Consistent system shape: ducting retains a clean look even when not in operation

Long service life: internal stainless steel rings (3–4 mm) absorb pressure shocks and reduce material strain

Easy handling: spacing of 500 or 1000 mm, secured with Velcro for quick installation and maintenance

Flexible use: suitable for diameters from 200–1270 mm; for smaller sizes, reinforcements are pre-installed, while for larger sizes, they are supplied for on-site mounting

Installing textile ducts is quick and straightforward. First, mount the aluminium rails or wire suspension system. Then simply slide or snap the duct into place using the pre-attached fasteners. Finally, connect it to the air supply using straps or a frame.

The entire process is simple and can be handled by two installers in just one morning. To make it even easier, we include illustrated manuals with every order, or you can view them directly on our website. We've also created short instructional videos that guide you step by step through the whole installation.

Clear step-by-step guides to help you install Euro Air textile ducts correctly and efficiently.

Practical video guides for installing textile ducting. Each step is shown exactly as it happens on site.

Your premises, Our solution

Let us inspire you how to handle the air distribution in your project.

Our expert sales representatives are ready to advise you on design or handle any project.

With us, you can expect a response to your request within 24 hours.