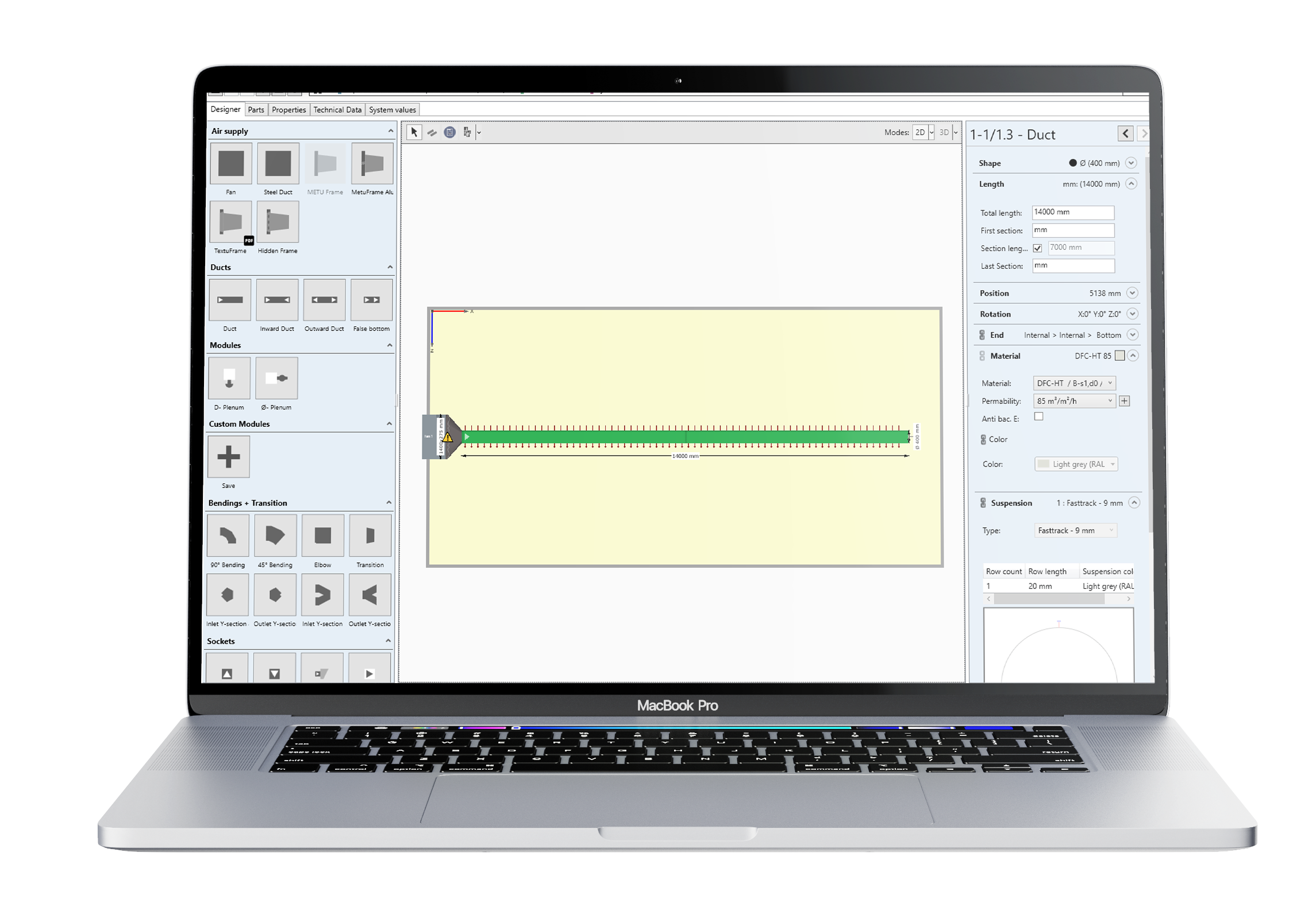

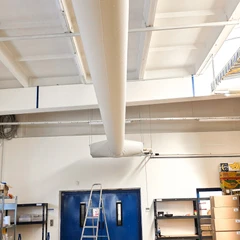

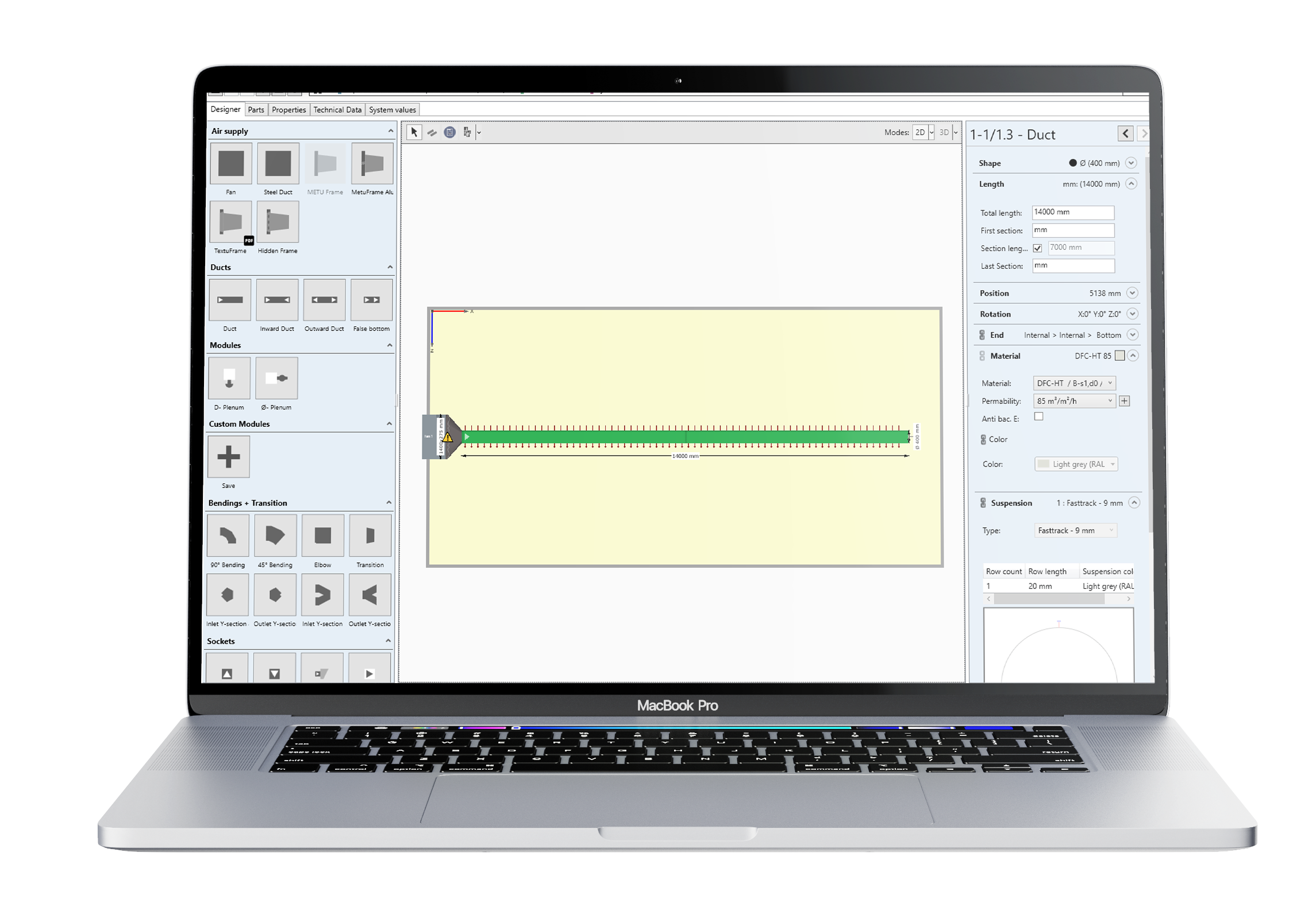

The textile vent has a circular cross-section with a diameter of Ø400 mm and is connected to a duct unit measuring 1400×275 mm. A MetuFrame AluTex mounting frame was used for the connection, allowing a direct and secure connection between the textile system and the sheet metal ductwork.

The system supplies a total of 2100 m³/h of air to the space. During operation, it reaches a maximum pressure loss of 114 Pa and maintains the sound power level at 56 dB(A).

DFC-HT material with an air permeability of 85 m³/m²/h was used for the installation. This material is made from high-tenacity polyester fibres woven in a plain weave. Production takes place in our own weaving mill in Vejen, Denmark, allowing for direct quality control and consistent parameters.

The material complies with fire classification EN 13501: B-s1, d0. Thanks to its versatility, it is also suitable for use in environments with high air cleanliness requirements, including ISO Class 4 cleanrooms. However, such specification was not required in this particular case.

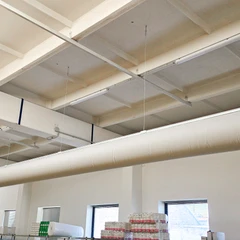

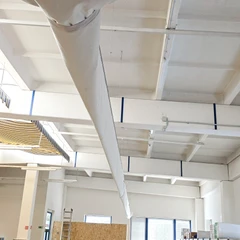

The textile duct is equipped with DFC perforation in the Comfort variant, which was designed to ensure uniform and stable airflow throughout the entire warehouse space. The perforation is arranged in five rows symmetrically distributed along the length of the duct.

Through these perforation rows, 32% of the total air volume is distributed, while the remaining 68% is supplied evenly through the permeable surface of the material. This distribution enables a combination of directional air delivery and diffuse surface flow, without the risk of dead zones or unwanted airflow directed at stored materials. The average air velocity in the occupied zone reaches 0.2 m/s.